Surve No. 682/1, Bhosari, Pune - 411039

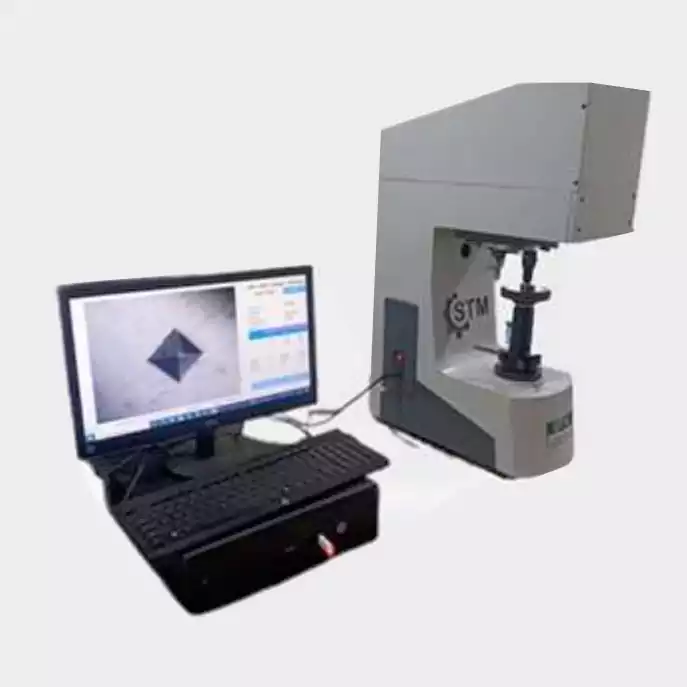

We are Manufacturer, Supplier, Distributor, Trader, Exporter, Importer of Load Cell Based Semi Automatic Micro Vickers Hardness Testing Machines (Hardness Testers) and our set up is situated at Pune, Maharashtra, India.

Our LMV-1 Micro Vickers Hardness Tester model is a unique product combining the robust mechanical welded structure design and load cell control system in the table-top version. This instrument has a servo controlled close-loops loop feedback control system, which controls the load within 1% accuracy of load cell capacity.

The machine’s mechanical and electronic system neither requires levelling of machine nor any specific

environmental conditions. This instrument consists of a one-touch calibration system with high linearity.

Suitable for harsh environment condition. (Temperature range: -10°c to 40°c)

The LMV-1 machine is powered by our own Software, equipped with easy-to-understand icons and workflows, Universal makes it simple to train users and set up tests, helping you maximize lab efficiency while minimizing costly errors. Self-guided software interface which will minimise errors in testing, and gives error free results. This machine based on INDUSTRY 4.0 having latest technology IoT SYSTEM.

MACHINE APPLICATION :

This models from the wide range of applications suitable for Labs, Heat Treatment Departments, Schools, Tool Rooms, Inspection Labs, Factories, etc. Suitable for all types of metals and non-metals, steel products, nonferrous materials, aluminium and soft alloys etc.

Also, can be used for plastics and composite materials like carbon fibre, Bakelite etc.

Technical Data :

| Scales | Micro-Vickers | Hv |

| Scales | Hardness Conversion | ASlM E140, DIN EN IS050150, DIN EN ISO 182265. |

| Test Forces | 0.010-2 kgf | 0.098-19.62 N |

| System | Load cell based, close loop force feedback system. | |

| Hardness Readings | Directly On Touch Screen With limit indications. | |

| Hardness least count | 0.1 Hv | |

| Load accuracy | as per standard <1% | |

| Load sampling rate | 400 samples per seconds | |

| Load cell capacity | 2 kgf | |

| Camera | 1.2 JV[p | |

| Field of view | 150 Microns | |

| Dwell Time | 00-99 Sec | |

| Connectivity | USB-3.0 for data output | |

| Connectivity | RJ45 for PC computer software connectivity for heat and batch repmt | |

| Spindle | Made of CAST-IRON, with a universal anvil attachment system. | |

| Max. Height of the Specimen (H) | 250mm | |

| Tln·oat depth (D) | 135mm | |

| Power Supply | Single phase, 50 Hz, 210-240 volts. | |

| Power Supply | Energy efficient (Power consumption only during test cycle) | |

| Machine Environment | -10°c to 40°c | |

| Dimensions | Machine Dimensions | 250x460x900mm |

| Dimensions | Packing Dimensions | 390x600x1100mm |

| Weight | Machine Net Weight | 100 Kg |

| Weight | Gross Weight | 120 Kg |

Standard Accessories :

| Sr.NO | DESCRIPTION | QTY |

| 1 | Main unit LMV -1 | 01 |

| 2 | Main unit cover (Anti dust cover for machine) | 01 |

| 3 | Anti-dust cover for main spindle | 01 |

| 4 | 0 100 mm round shaped test table | 01 |

| 5 | "V" shaped anvil up to 0 38 mm round job | 01 |

| 6 | Standard test blocks | 01 |

| 7 | Indenter | 01 |

| Micro-Vickers diamond indenter | 01 | |

| 8 | Power chord | 01 |

| 9 | Fuse 2 Amp | 02 |

| 10 | Allen key set | 01 |

| 11 | Screw driver | Ol |

| 12 | Rest pad | 04 |

| 13 | Clamping cone for safety | 01 |

| 14 | Machine Pen drive | 01 |